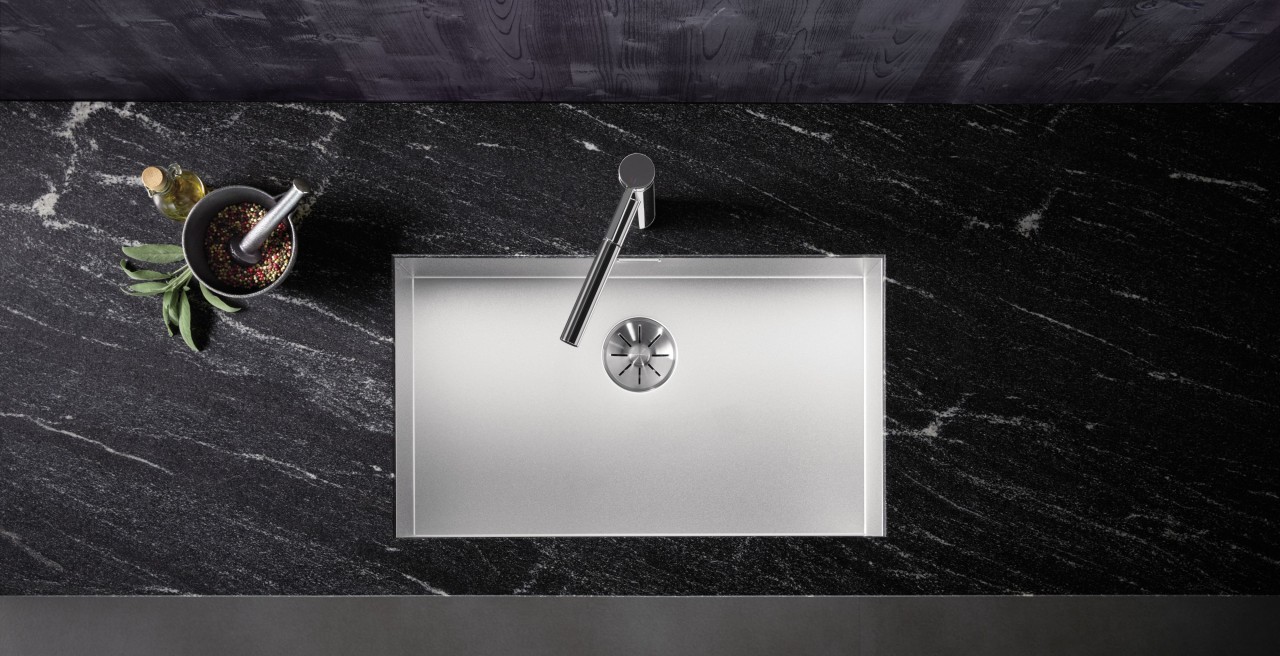

The new stainless steel surface will delight anyone who loves the coolly elegant look of stainless steel and also appreciates a resistant surface. Durinox is distinctive for its velvety-matte look and pleasant feel, while it is also impervious to scratches and fingerprints. Thanks to its special surface texture, Durinox Stainless steel is easier to clean and care for in the kitchen.

High-speed blasting at over 300 km/h

During the process for producing the Durinox surface, 1 billion minuscule stainless steel balls are blasted at a speed of almost 300 km/h into a stainless steel sheet only 1 mm thick. The result is highly impressive: the blasted stainless steel is over twice as hard as conventional stainless steel surfaces, and has a distinctive, particularly elegant look. As a result, we have filed a patent for the entire process.

One surface. Countless designs.

High-speed blasting at over 300 km/h

During the process for producing the Durinox surface, 1 billion minuscule stainless steel balls are blasted at a speed of almost 300 km/h into a stainless steel sheet only 1 mm thick. The result is highly impressive: the blasted stainless steel is over twice as hard as conventional stainless steel surfaces, and has a distinctive, particularly elegant look. As a result, we have filed a patent for the entire process.

Pure stainless steel

The velvety-matte stainless steel surface created with this blasting process has the highest degree of hardness of any pure, uncoated stainless steel surface. And it’s not just the skin-deep. Durinox isn’t just a surface coating. Instead, the 1 mm-thick stainless steel sheet has been hardened all the way through, as it has been blasted from both sides. The Durinox surface is produced over several production runs until the material has the desired hardness and appearance.